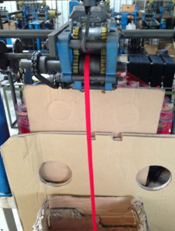

Stepl Yarn Webbing

Plain Lanyards are made in mass production. For cord lanyards, the diameter can be made to customer's specifications. As for flat lanyards, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm and even 30mm (w) are commonly used; customized width can also be made. The base color of the lanyard can be processed according to the Pantone color (with free color-matching assistance) if requested by customers.

Step2 Printing Process

For lanyards with logo/text printing, besides Woven-in logos through webbing process, we can also use Silk Screen Print or Dye Sublimation Heat Transfer to print images and text messages on the lanyards, either on one side (front side) or both sides of the lanyard.

Step3 Lanyard Assembly

At this stage, all of customer's preferred end attachments will be fitted onto the lanyards, such as a swivel hook, bulldog clip, split key ring, safety breakaway, quick-release buckle, etc. A metal crimp or stitching is applied to finish the lanyard. Then the lanyard is ready for packing.